Parts Feeder

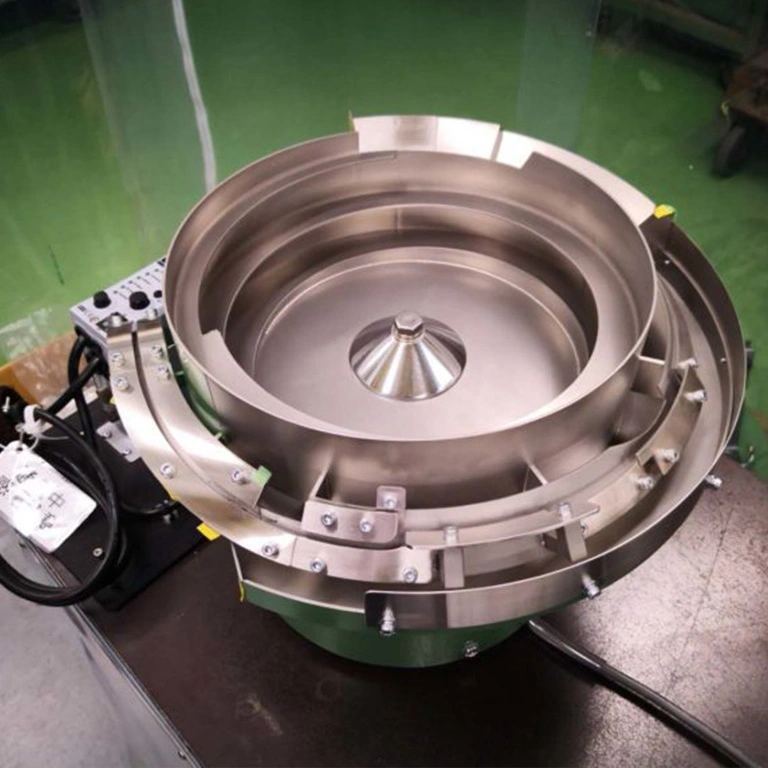

Vibration Bowl

Manufacturing technology

Our company adopts 3D aided design for the feeder, and the material is cut by CNC water cutting machine. Because it is cold cut, the stainless steel material is not easy to deform, so that the track is smoother, torsion is smoother, welding is seamless, and the damage to the track is avoided by grinding, so as to meet the requirement of efficient and trouble-free feeding. In addition, our company is also equipped with CNC bending machine, CNC cutting machine, CNC track torsion machine, imported low-temperature cold welding machine, imported open punching shears and other high-end sheet metal equipment. The application of these high-end sheet metal equipment, together with the domestic advanced vibration Bowl Sheet metal process masters, makes our company’s vibration Bowl and other forms of feeder to reach the highest level in the industry.

Vibrating bowl-type feeder

Top tray of stainless steel or CNC machining is installed on the upper part of electromagnetic type or piezoelectric type chassis drive. Inside the top tray, guide chutes are designed based on sorting posture requirements of parts to send out parts. This kind of feeder can be used together with linear vibrating disk if required to bring parts to a longer distance, and meanwhile, check sensors can be installed on the linear guide way to control on and off of the vibrating disk, thus reducing energy consu-mption and wear. This type of feeder can realize orderly feeding of parts with complex shapes as per requirements. As a substitute of manual labor, it effectively imp-roves work efficiency and reduces labor cost.

Centrifugal feeder

It uses motor to drive the vessel of barrel shape or bowl shape. A hanging device is installed inside the vessel to bring parts into holes during its rotation and send out parts orderly through the guide chute. This kind of feeder has a large range for speed adjusting, high discharge quantity, and enjoys advantages like low noise and high accuracy for parts that are easy to be sorted, therefore are widely applied in counting packaging industry.

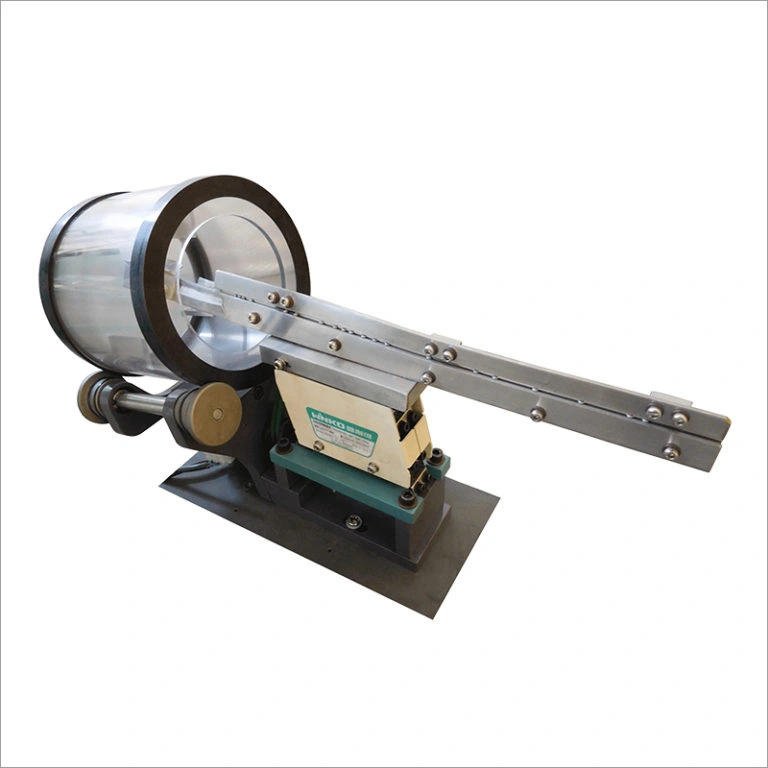

Cylinder feeder

It uses motor to drive the cylinder to rotate. The air vanes installed inside the cylinder can lift the parts from bottom to the linear guideway, and the parts are arranged in order and sent out by the sorting device on the guideway. This kind of feeder is compact, easy to install and has low vibration and noise, suitable for parts that have simple shapes and are easy to sort, such as bolts, rubber plugs, magnetic cores and other small parts.

Compressed air drive-type vibration feeder

The pneumatic vibrating disc and straight line are driven by compressed air instead of high frequency inductance coil. It will not produce electromagnetic wave, thermal radiation and static electricity, that is, it will not cause various combustion or explosion accidents. It is especially suitable for the transportation, screening and sorting of inflammable and explosive precise materials or powder particles which are not affected by

Spring separation-type vibration feeder

A spring separator is built inside the vibration disk-type feeder. The spring is sent into the separator through the guideway of the vibrating disk; the impeller that is rotating at high RPM separates the spring to the material receiving guideway. Windpipe for material blowing and removal of stuck materials is in-stalled at the outlet to realize full-process automation of spring including independent separation, independent feeding, independent removal of stuck materials. This kind of spring feeder can adapt widely and is the best choice in terms of spring feeding by automated assembled equipment.